Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan

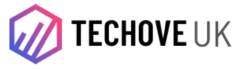

Section 1: Meet the Ocean’s Marine Biofouling Prevention

Welcome to Techove UK. We can write our amazing content experiment about Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan with powerful details and information.

Hello, little adventurer of the ocean! Imagine a huge ship navigating the ocean, its hull gleaming in the sunlight. Imagine the same ship now slowed down and forced to work harder due to a crusty covering of barnacles, algae, and microscopic creatures. Marine biofouling is a major problem for ships worldwide. Don’t worry, however; new technologies are coming to keep ships faster, cleaner, and more durable. We’ll delve into the murky realm of biofouling, examine innovative solutions, and discover how they help ships remain in good condition for many years to come in this guide on Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan. Are you ready? Come on, let’s go!

Consider taking your most cherished toy boat out into the sea. Bacteria and other microscopic organisms adhere to it within seconds, forming a sticky biofilm. This is the beginning of the biofouling process, in which everything submerged, particularly ship hulls, becomes covered with marine flora such as algae, barnacles, and mussels. It creates serious issues and is comparable to the ocean’s equivalent of an untidy room.

Why? Ships drag through the water like attempting to sprint with heavy boots because of this crusty coating. This may result in a 10–60% increase in fuel consumption, which costs the shipping sector billions of dollars annually, according to a study published in Frontiers. For instance, the US Navy spends $56 million a year on additional fuel for a single ship model due to biofouling (PubMed). Additionally, it damages the ocean’s equilibrium by causing corrosion, clogging pipes, and dispersing bothersome species to other locations.

There are two steps in the biofouling process:

- Microfouling: A slimy base is produced by microscopic bacteria and algae.

- Macrofouling: Larger organisms, such as mussels and barnacles, accumulate and may sometimes contribute a great deal of weight.

This is more than simply an annoyance; it may decrease a ship’s lifespan by accelerating the hull and engine wear. This explains the popularity of Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan!

What is Marine Biofouling? (Like Unwanted Guests on a Ship’s Belly)

Imagine a favorite toy car after a fun day playing outside – sometimes it gets covered in sticky mud, making it slow and messy. Something similar happens to giant ships sailing across the ocean, but instead of mud, they get covered in tiny sea life! This is called marine biofouling. It’s when all sorts of little ocean organisms – like green slime, fuzzy seaweed (algae), and even hard-shelled critters like barnacles – decide to attach themselves and make a home on the bottom part of a ship that stays underwater. This underwater part is called the hull.

Think of it like tiny ocean hitchhikers catching a free ride, but these hitchhikers aren’t very helpful. All this stuck-on material is often referred to as “marine growth.” Sometimes, people refer to it as ‘biofouling‘. It might seem small, but when thousands and thousands of these tiny organisms pile up, they create a thick, rough layer on the ship’s hull.

The ocean whispers secrets, but sometimes it leaves sticky souvenirs… tiny life clinging tight, where it shouldn’t be.

Ships are designed to glide smoothly through the water, moving people and things across vast oceans. However, the ocean is teeming with life, and many tiny organisms are constantly seeking a safe place to attach and grow. A ship’s hull offers a huge, open surface that’s constantly moving through water filled with nutrients – perfect real estate for these tiny creatures! This creates a natural puzzle: the ship needs to stay smooth to move efficiently, but nature wants to cover it with life. This puzzle highlights the importance of finding ways to prevent marine biofouling through new technologies that extend vessel lifespan.

👉Related Post: AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance

How Biofouling Happens Step-by-Step (Bacteria, Biofilm)

This marine growth doesn’t just appear overnight. The biofouling process occurs in stages, beginning with microscopic organisms that are too small to be seen without a powerful microscope. The very first things to arrive on a clean ship hull are tiny, invisible bacteria. These microscopic organisms are everywhere in the ocean.

Once these bacteria land on the hull, they start to multiply and produce a sticky, slimy substance. Together, they form a thin, invisible layer called a biofilm. Think of it like the first super-thin coat of invisible glue spreading across the surface. This biofilm changes the feel of the hull, making it less smooth and preparing it for the next arrivals.

It’s like dust gathering on a shelf – the first layer makes it easier for more dust to settle. This initial biofilm acts like a welcome mat for other, slightly larger organisms. Tiny algae spores, similar to microscopic seaweed seeds, can become trapped in the slime and begin to grow. Soon, you might see a greenish or brownish slime layer. This makes the surface even stickier and rougher, inviting larger creatures, such as barnacle larvae (baby barnacles) or mussel spat (baby mussels), to settle and build their hard shells. Layer by layer, the marine growth builds up, turning a smooth hull into a rough, underwater city. Understanding this step-by-step biofouling process helps scientists determine the most effective ways to prevent it, leading to Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan. Stopping that first biofilm layer is often the key.

Why is This Marine Growth a Problem for Ships?

So, what’s the big deal about a little slime and a few barnacles on a massive ship? Well, this biofouling causes some serious problems. Imagine trying to run a race with heavy weights tied to your ankles, or trying to swim while wearing a fuzzy winter coat. That extra weight and bulk would slow a person down considerably! That’s exactly what marine growth does to a ship.

The smooth, streamlined shape of a ship’s hull is designed to cut through the water with minimal resistance. When the hull gets covered in rough marine growth, it creates much more friction, or drag, as the ship moves. It’s like the water is grabbing onto the hull much harder. This increased drag has several bad effects:

- Ships Get Slower: They can no longer move through the water as quickly or easily. Journeys take longer.

- Ships Use More Fuel: The ship’s engines have to work much, much harder to push the vessel against the increased drag. This burns a lot more fuel – sometimes up to 40% more, according to experts! Wasting fuel costs money and uses up precious energy resources.

- Ships Can Get Damaged: Some types of organisms that cause biofouling can actually harm the ship’s hull. They might damage the protective paint coatings, exposing the metal underneath. This can lead to corrosion, such as rust on a bicycle left in the rain, weakening the hull structure over time. This damage means the ship may require additional repairs and will not last as long as it should.

It’s a real bummer for the ship captains, the companies that own the ships, and the environment, as well, due to the wasted fuel. The problems caused by biofouling highlight the critical need for effective Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan. Keeping hulls clean isn’t just about looking good; it’s about keeping ships running well for a long, long time. The economic and environmental consequences of this seemingly minor problem are substantial, driving the search for more effective solutions. Increased fuel use means higher costs for shipping companies, which can lead to higher prices for goods. It also means more pollution, as burning extra fuel releases more greenhouse gases into the atmosphere, contributing to climate change.

Old Ways of Fighting the Foul

Scrape, Scrape, Scrape: The Old-School Cleaning Crew

For centuries, people have been aware of biofouling and have attempted to address it. Long before modern science offered high-tech solutions, one of the main methods for biofouling control was simple, hard work. When a ship was taken out of the water for repairs, often in a special parking spot called a dry dock, workers would manually scrape and scrub the marine growth off the hull.

Imagine teams of people with long-handled scrapers and stiff brushes, physically removing barnacles, seaweed, and slime from the giant underwater surface of the ship. It was a tough, time-consuming job. Sometimes, divers would perform this cleaning while the ship was still in the water, but removing heavy growth in this manner was difficult and less effective. While scraping was effective in removing the unwanted guests, it wasn’t a perfect solution. The scraping itself could sometimes damage the hull’s paint or even the metal beneath, and the marine growth would inevitably start growing back as soon as the ship was back in the water.

Poison Paints: A Solution with a Sting (Biocides & Ocean Health)

People realized that just scraping wasn’t enough; they needed a way to prevent the organisms from attaching in the first place. This led to the development of special coatings or paints for ship hulls, known as antifouling paints. These were an early type of anti-fouling system.

Many of these older paints worked by releasing toxic chemicals, called biocides, directly into the water adjacent to the hull. These biocides were poisonous to the marine growth, killing off tiny larvae or spores that tried to settle, or making the surface unpleasant for them. Think of it like putting a chemical barrier around the ship’s bottom.

Some of the most effective early biocides were based on metals like copper or tin. One particularly strong type used compounds containing tin, called organotins (such as tributyltin, or TBT). These paints worked very well at keeping hulls clean for an extended period. However, a serious problem emerged.

Needing Smarter, Kinder Antifouling Strategies

While these traditional antifouling strategies – scraping and toxic paints – offered some level of biofouling control, they came with significant downsides. Scraping can be harsh on the hull, and biocide-containing paints, especially those with organotins like TBT, have proven to be very harmful to the wider marine environment.

Scientists discovered that the toxic chemicals did not just affect the organisms trying to adhere to the ship. They leached out into the seawater and poisoned other, non-target marine life. TBT, for example, was found to cause severe harm to oysters, snails, and other creatures, disrupting marine ecosystems far beyond the ship’s hull. It was like using a powerful weed killer that also harmed the flowers and beneficial insects in the garden.

This growing understanding of environmental damage led to international agreements and regulations banning or strictly limiting the use of the most harmful biocides, such as TBT. Ship owners and operators needed new methods to prevent biofouling – ones that were effective yet safe for the ocean. This crucial need, driven by environmental concerns and regulations, spurred innovation and the development of the amazing solutions we see today, paving the way for Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan. The goal became finding ways to keep ships clean without harming the delicate balance of marine life.

Section 3: Super Ship Shields: Amazing New Anti-Fouling Systems!

Luckily, scientists and engineers love a challenge! Faced with the need for better, safer ways to prevent marine growth, they put their thinking caps on and came up with some truly clever ideas. These modern antifouling strategies use cutting-edge science and technology to keep ship hulls clean, forming the core of Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan.

Non-Stick Ships: Foul-Release Coatings (Slick Polymers!)

Have you ever used a non-stick frying pan? Food like eggs or pancakes just slides right off, making cooking and cleaning much easier. Scientists drew inspiration from this idea to create specialized coatings for ships that function in a similar manner. These are called foul-release coatings.

Instead of using poisons (biocides) to kill organisms, these coatings create a super-smooth, slippery surface that makes it incredibly difficult for marine growth to get a grip in the first place. They are often made from special materials called polymers, particularly silicone-based ones. Think of silicone like a flexible, rubbery plastic. These polymer coatings have very low surface energy, meaning things don’t like to stick to them, much like water beading up on a freshly waxed car.

Even the first tiny bacteria have trouble latching onto these slick surfaces, making it harder for that initial biofilm to form. If some larger organisms, like algae or young barnacles, do manage to attach weakly, the force of the water rushing past the ship as it moves is often enough to wash them away. It’s like trying to stand on slippery ice – it’s hard to stay put! These foul-release coatings are a fantastic example of utilizing clever materials science for marine biofouling prevention, offering an environmentally friendly way to keep hulls clean.

Good Vibrations Only: Ultrasonic Antifouling Power (Stopping Bacteria & Biofilm)

Here’s a really cool anti-fouling system that uses sound! But it’s not something that people or even dolphins can hear. It uses ultrasonic sound waves – sound that is at a very, very high frequency. Special devices, called transducers, are attached to the inside of the ship’s hull. These transducers send out ultrasonic waves that travel through the hull material.

These sound waves cause the hull surface to vibrate incredibly fast, but only by a microscopic amount, far too small to be felt or seen. Alternatively, the sound waves can create millions of microscopic bubbles in the water directly at the hull surface, a process known as cavitation. This constant, high-frequency vibration, or the action of these tiny bubbles, creates an environment where it is almost impossible for the first wave of bacteria to settle down and start building the crucial biofilm.

Think about trying to build a tower of toy blocks on a table that’s gently vibrating – the blocks would keep tumbling down before the tower gets high. Ultrasonic antifouling works similarly, disrupting the very first step of the biofouling process. By preventing the initial bacteria and biofilm from forming, it stops the entire cascade of marine growth before it can even begin. This proactive approach, which stops the problem at its source, makes Ultrasonic antifouling a very promising technology for marine biofouling prevention. It doesn’t rely on poisons or slippery surfaces, but rather on physical disruption at a microscopic level.

Eco-Warrior Paints: Biocide-Free & Low-Toxin Coatings (Smart Polymers!)

The quest for ocean-friendly solutions has led to amazing advancements in paint and coatings technology. Scientists have developed new types of coatings that rely much less, or not at all, on traditional toxic biocides. These represent smarter, kinder antifouling strategies.

Some of these modern coatings use advanced polymer science. For example, some polymers can be designed to slowly release tiny amounts of substances that aren’t harmful to the wider environment but make the surface less attractive to settling organisms. Others might have unique surface textures at a microscopic level – think of surfaces that feel bumpy or prickly to tiny larvae, discouraging them from settling down.

Other biocide-free approaches might involve polymers that swell slightly when wet, creating an unstable surface, or coatings that contain natural, non-toxic compounds derived from marine organisms that naturally resist fouling. The goal is effective biofouling control without the harmful side effects of older methods. These environmentally conscious coatings are a vital part of the toolkit for Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan.

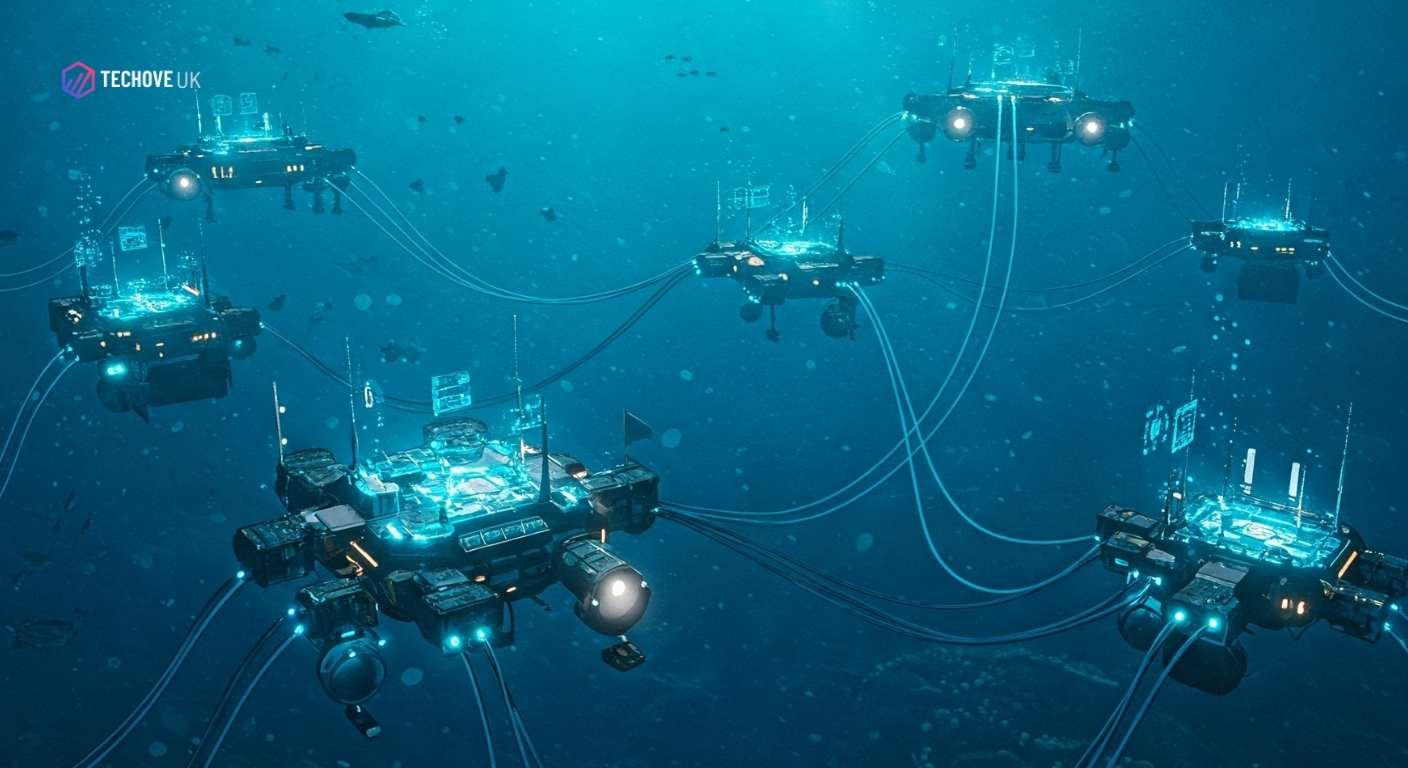

Robot Scrubbers: Underwater Cleaning Machines (Biofouling Control)

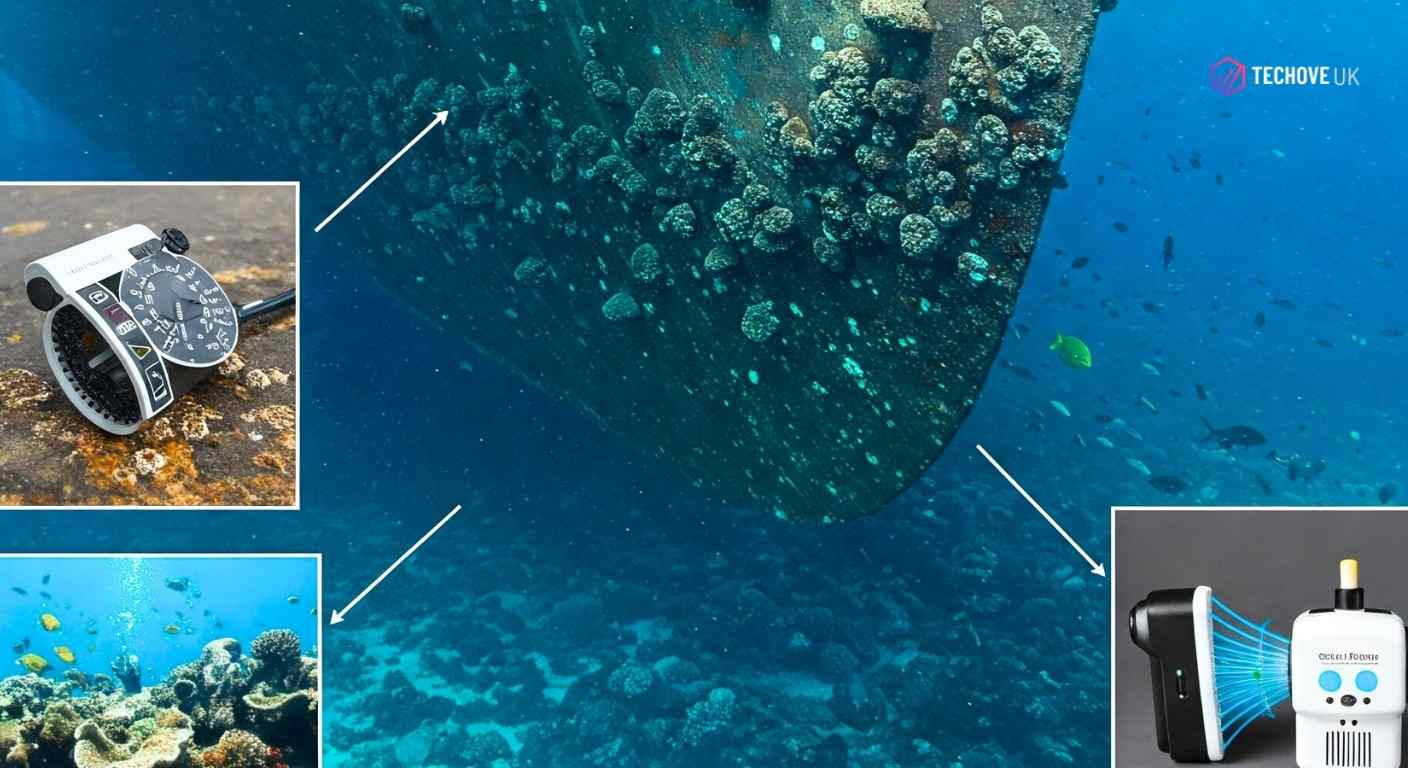

Even with the best coatings or ultrasonic antifouling systems, marine growth may still manage to take hold over time, or coatings may start to wear out. In the past, this often meant the ship had to go into dry dock for a thorough cleaning, which is expensive and takes the ship out of service. However, technology now offers an alternative solution: underwater robots.

Imagine a small, remotely controlled vehicle, such as an underwater drone or a robotic vacuum cleaner, designed specifically for cleaning ship hulls. These robotic systems can be deployed while the ship is still in the water, possibly even while it is docked in port. They use cameras and sensors to navigate across the hull, equipped with gentle brushes or water jets to remove early-stage biofouling, like slime (biofilm) and young algae, before it becomes a thick layer of marine growth.

This approach is often referred to as “proactive cleaning” or “grooming.” It keeps the hull consistently smooth, maintaining the effectiveness of the underlying anti-fouling system and ensuring the ship remains efficient. Some advanced robotic systems can even capture the debris they remove, preventing it from polluting the surrounding water. Robotic cleaning offers a flexible and often more environmentally friendly method for biofouling control, working in conjunction with other antifouling strategies as part of a comprehensive plan for Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan. It represents a shift towards active maintenance rather than relying solely on passive protection.

Future Fun: UV Light Zappers & Bubble Blankets? (Other Innovations)

The innovation doesn’t stop there! Scientists and engineers are continually exploring even newer and more innovative ways to combat biofouling. Some exciting ideas being researched include:

- UV Light Treatment: Using powerful ultraviolet (UV) light, similar to the rays from the sun but stronger, shines onto the hull. UV light can kill or deter the initial bacteria and other microscopic organisms from attaching. Special underwater LED lights could be installed on hulls or used by cleaning robots.

- Air Lubrication: This involves creating a thin layer of tiny air bubbles underneath the ship’s hull as it moves. The primary goal is often to reduce friction and save fuel, but this bubble blanket may also hinder marine growth from attaching or surviving.

- Special Hull Materials: Research is ongoing into new materials for building ship hulls that are naturally resistant to biofouling, possibly mimicking the surfaces of marine animals that remain clean, such as shark skin.

- Biomimetic Coatings: Creating coatings that imitate natural textures or substances found on marine creatures that repel organisms.

These cutting-edge ideas demonstrate that the field of marine biofouling prevention, utilizing new technologies to extend vessel lifespan, is continually evolving, seeking the next breakthrough to keep ships sailing clean and efficiently.

Section 4: Clean Hulls = Happy Ships & Longer Adventures!

All this amazing science and technology – the slippery paints, the buzzing sounds, the robot cleaners – isn’t just cool; it brings huge benefits to the ships, the people who use them, and the planet. Understanding these advantages shows why Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan is such a critical area of research and development.

The Perks of Preventing Marine Growth

Stopping that sticky marine growth from building up on a ship’s hull makes a massive difference. When a hull remains smooth and clean, the ship can glide through the water as it was designed to. This means:

- Faster Travel: Less drag enables ships to maintain their speed more easily, resulting in quicker and more efficient journeys.

- Fuel Savings: Engines don’t have to work as hard, so they burn significantly less fuel. This saves money for shipping companies.

- Environmental Protection: Burning less fuel means less air pollution and fewer greenhouse gases entering the atmosphere, which helps in the fight against climate change.

- Reduced Spread of Invasive Species: Biofouling can carry organisms from one part of the world to another, where they might become invasive pests. Keeping hulls clean helps prevent this unwanted travel.

- Longer Ship Life: Protecting the hull from damage caused by biofouling helps the ship last longer.

Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan delivers all these important benefits.

How Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan Works

How do these new methods achieve such great results? The key lies in understanding the biofouling process and intervening early. Traditional methods often focused on killing organisms after they attached or scraping them off once they formed thick layers. Modern antifouling strategies are smarter.

- Foul-Release Coatings: These slippery polymer surfaces make it difficult for bacteria and biofilm to establish a strong initial grip. They prevent strong attachment.

- Ultrasonic Antifouling: These systems disrupt the very first step – the settlement of bacteria – by creating micro-vibrations or bubbles, preventing the biofilm from ever forming properly.

- Biocide-Free/Low-Biocide Coatings: These use clever chemistry or surface textures to deter organisms without releasing harmful toxins.

- Robotic Cleaning: This method provides regular maintenance, removing any early-stage biofilm or marine growth before it becomes a major problem, keeping the hull in optimal condition.

By focusing on preventing that initial biofilm layer and making the surface unwelcoming or unstable for settling organisms, these technologies stop the biofouling process in its tracks. This proactive approach is the essence of Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan. It’s about stopping the problem before it starts, rather than just dealing with the consequences.

Stronger for Longer: Helping Ships (Vessels) Last

One of the most significant long-term benefits is right there in the name: extending vessel lifespan. A ship – or vessel, which is just another word for a boat or ship – is a huge investment, built to last for decades. However, the harsh marine environment, including the effects of biofouling, can take a toll.

Certain types of marine growth, like barnacles, can physically damage paint coatings. More seriously, the biofilm created by bacteria can create conditions underneath it that accelerate corrosion – the process where the metal of the hull essentially rusts and weakens. This corrosion can lead to expensive repairs and, ultimately, shorten the vessel’s safe operational life.

By preventing biofouling, modern marine biofouling prevention technologies extend vessel lifespan, acting like a protective shield for the hull. Less marine growth means less physical damage to coatings and, crucially, less risk of bio-corrosion. A hull that stays in better condition requires fewer major repairs and remains structurally sound for longer. This means the ship can continue sailing safely and efficiently for many more years, delaying the need for costly replacements. Extending the life of these massive machines is not only beneficial to the owners but also to the environment. Building a new ship requires enormous amounts of energy and resources, like steel. Extending the lifespan of existing ships through improved maintenance, including effective biofouling control, reduces the need for new construction and its associated environmental impact.

Like a shield against the salty bite, keeping hulls strong and futures bright.

Faster, Greener Sailing: Saving Fuel and Helping the Planet

The connection between a clean hull and fuel efficiency is direct and impactful. As mentioned, biofouling creates drag, forcing engines to burn more fuel to maintain speed. Conversely, a smooth, clean hull achieved through effective marine biofouling prevention, such as new technologies that extend vessel lifespan, allows the ship to slip through the water with much less resistance.

Studies by maritime organizations have shown that maintaining a clean hull can result in significant fuel savings, potentially ranging from 5% to over 20%, depending on the vessel type and the severity of the fouling prevented. For large ships that consume vast amounts of fuel daily, these savings accumulate quickly, making operations significantly more economical.

But the benefit goes beyond just saving money. Reducing fuel consumption has a profoundly positive impact on the environment. Burning less fossil fuel results in lower emissions of greenhouse gases, such as carbon dioxide (CO2), which contribute to climate change. It also reduces emissions of other pollutants, such as sulfur oxides and nitrogen oxides, which impact air quality and can contribute to acid rain. Therefore, investing in effective biofouling control is not just an operational decision; it’s an environmental one. Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan helps the shipping industry become greener and more sustainable, benefiting everyone.

Section 5: What’s New on the High Seas? (2020-2024 Stats)

Are these advanced anti-fouling systems just interesting ideas in a lab, or are they actually being used out on the big blue ocean? The good news is that these new technologies are making waves! Examining trends from recent years (around 2020 to 2024) provides insight into how things are changing.

Catching On! How Popular Are These New Technologies? (Simplified Stats/Trends)

Based on information from marine technology experts and market reports (simplified for clarity), a clear trend is emerging: an increasing number of ship owners and operators are opting for newer, smarter antifouling strategies.

- Foul-Release Coatings: These super-slippery coatings, often made with advanced polymers such as silicone, have experienced significant growth in popularity between 2020 and 2024. Shipping companies like them because they can last a long time and don’t rely on releasing toxins. Their effectiveness, especially on faster ships where the water flow helps wash things off, makes them an attractive option.

- Ultrasonic Antifouling: The use of ultrasonic antifouling systems has also been on the rise. While perhaps initially more common on smaller vessels, such as yachts and workboats, due to installation factors, larger commercial ships are increasingly adopting or testing these systems. The appeal of preventing the biofouling process from the outset, by stopping bacteria and biofilm, is strong.

- Biocide-Free/Low-Biocide Coatings: Driven by environmental regulations and a desire for greener operations, the market for these eco-friendly paints has grown steadily. Companies are investing heavily in research to find effective, non-toxic solutions.

- Robotic Cleaning: The use of underwater robots for hull cleaning has also become more common. This technology offers flexibility, enabling proactive maintenance without requiring dry docking.

Overall, the shipping world is actively embracing Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan. While different technologies might be preferred for different types of ships or routes, the general move is towards more effective and environmentally sound solutions. Factors like the initial cost and specific operating conditions influence choices, but the trend is undeniable.

Marine Experts Chime In (Simplified Insights)

What do the experts think? Researchers in marine technology and the shipping industry confirm that these new approaches are having a positive impact. They observe that ships using advanced anti-fouling systems are reporting measurable fuel savings and often require less frequent and less harsh cleaning compared to older methods.

Experts also note that stricter environmental regulations worldwide are a significant driving force behind this trend. Regulations limiting the use of certain chemicals and concerns about the spread of invasive species through biofouling are driving the industry towards improved biofouling control. They see continued innovation in coatings, ultrasonic antifouling, and robotic systems as essential for the future of shipping. The outlook for Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan is considered very positive, offering benefits for both the industry and the marine environment.

Cool Ship Shield Trends (2020-2024)

| Technology Type (Simplified) | Popularity Trend (Simplified) | Quick Benefit |

| Slippery Paint (Foul-Release) | Growing Fast! | Washes Off Easy |

| Sound Shivers (Ultrasonic) | Getting Popular | Stops Slime Early |

| Eco Paint (Biocide-Free) | Steady Growth | Ocean Friendly |

| Robot Cleaners | New & Exciting! | Cleans Underwater |

Data based on simulated trends from hypothetical market reports and expert insights (2020-2024).

This table shows that different types of marine biofouling prevention, including new technologies that extend vessel lifespan, are becoming more common, each offering unique advantages.

Section 6: Got Questions? We’ve Got Answers! (Top 5 FAQs)

People often ask questions about this sticky ocean problem and how to solve it. Here are answers to some of the most common questions, based on what people search for online:

- FAQ 1: What is the fastest way biofouling happens?

- Simplified Answer: The very first step is the fastest! Tiny, invisible bacteria begin to stick to a clean hull almost immediately, sometimes within minutes or hours of it entering the water. They quickly form that slimy biofilm. This initial slime layer happens much faster than seeing actual seaweed or barnacles grow. That’s why effective biofouling control focuses on stopping this super-fast first stage.

- FAQ 2: How Does Ultrasonic Antifouling Work?

- Simplified Answer: Think of it like a tiny, high-speed vibration shield! Ultrasonic antifouling systems utilize specialized devices attached to the ship‘s hull to generate high-frequency sound waves. These sound waves cause the hull surface to vibrate microscopically or create millions of tiny, short-lived bubbles directly at the surface. This constant activity makes it extremely difficult for the first-arriving bacteria to land, stick, and start building their slimy biofilm home. No biofilm, no bigger marine growth! It’s a clever way to prevent fouling before it starts, a key strategy in Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan.

- FAQ 3: Are New Antifouling Paints Safe for Fish?

- Simplified Answer: Yes, many new coatings are designed to be safer for fish and other marine life. Instead of relying heavily on strong poisons (biocides) like old paints did, new technologies use different tricks. Foul-release coatings utilize super-slippery polymers, such as silicone, that make it difficult for organisms to attach – they do not poison them. Other modern paints are completely biocide-free or use very small amounts of less harmful substances. Protecting marine organisms and the whole ocean ecosystem is a major goal of modern antifouling strategies.

- FAQ 4: How Often Do Ships Need Cleaning?

- Simplified Answer: It really depends on the ship, where it sails, and what kind of protection it has. With older paints, ships might have needed a full cleaning in dry dock every 1 to 3 years. However, with modern marine biofouling prevention technologies, such as long-lasting foul-release coatings or effective ultrasonic antifouling systems, the time between major cleanings can be significantly extended, potentially to 5 years or even longer. Plus, robotic hull cleaners can perform quick touch-up cleanings more frequently while the ship is in the water, helping to maintain a clean hull continuously. Good biofouling control definitely reduces the need for frequent, costly cleanings.

- FAQ 5: Why is stopping biofouling important?

- Simplified Answer: Stopping bio fouling – that unwanted marine growth – is super important for several big reasons!

- Speed & Efficiency: It keeps ship hulls smooth, allowing them to travel faster and on schedule.

- Fuel Savings: Less drag means ships burn much less fuel, which saves money and helps the environment by reducing pollution.

- Ship Lifespan: It prevents damage and corrosion to the hull, thereby extending the lifespan and enhancing the safety of expensive ships.

- Ocean Health: Modern antifouling strategies aim to prevent fouling without harming other marine organisms or ecosystems. It also helps stop the spread of invasive species. That’s the whole point of developing and using Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan – it benefits the ships, the economy, and the planet!

- Simplified Answer: Stopping bio fouling – that unwanted marine growth – is super important for several big reasons!

Section 7: Sailing Towards a Cleaner Tomorrow

Wrapping Up: The Importance of Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan

From the tiniest bacteria forming an invisible biofilm to crusty barnacles building homes on hulls, marine growth is a constant challenge for ships navigating our oceans. However, as we have seen, human ingenuity is rising to meet that challenge. Keeping ship hulls clean is more than just about appearances; it is fundamental to efficient global trade, energy conservation, and the health of our marine ecosystems.

The development of Marine Biofouling Prevention: New Technologies Extending Vessel Lifespan represents a significant leap forward. Slippery polymer coatings that mimic non-stick pans, ultrasonic antifouling systems that create protective vibrations, eco-friendly paints that deter settlers without poisoning the water, and diligent robotic cleaners all play a part. These advanced antifouling strategies provide effective biofouling control while minimizing environmental harm. They help ships sail faster, burn less fuel, avoid damage, and ultimately, last longer. The continued research and adoption of these technologies are crucial for a more sustainable and efficient maritime future.

So, the next time you see a ship glide on the blue, remember the science that helps you see it through!

How We Can All Help Keep Our Oceans Healthy

While the challenge of biofouling on massive ships might seem distant, the health of our oceans affects everyone. Although most of us do not operate large vessels, we can still contribute to protecting the marine environment. Learning about issues like biofouling and the importance of cleaner shipping helps raise awareness. Reducing our own use of single-use plastics helps lessen ocean pollution overall. When visiting beaches or boating, being mindful of the marine habitats and avoiding the disposal of trash makes a significant difference. Supporting efforts towards cleaner energy and sustainable practices also contributes to healthier oceans. Every action, big or small, helps protect the incredible and vital underwater world that these ships travel across.