How AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance is Changing Our Seas!

Welcome to Techove UK. We can write our amazing content experiment about AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance with powerful details and information.

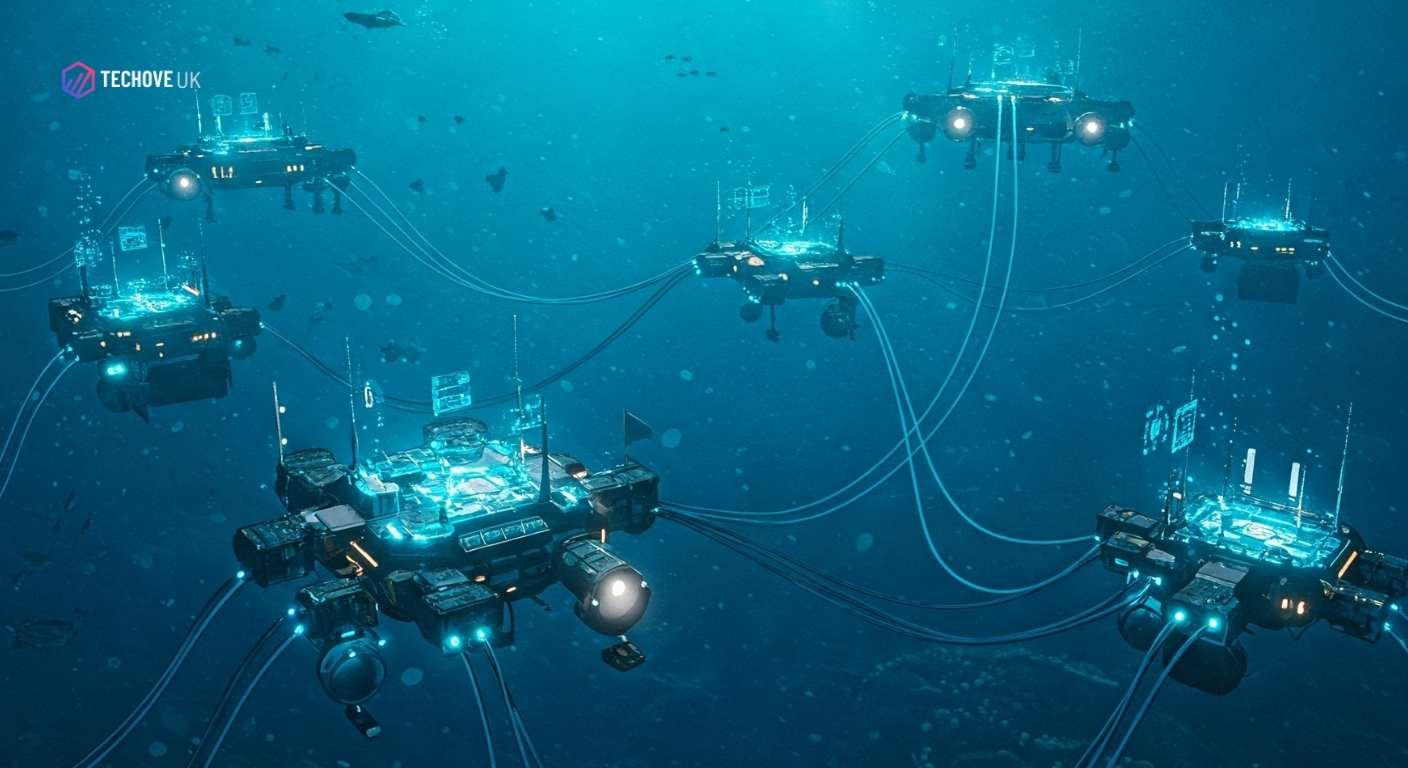

Imagine the ocean, wide and deep, a world of adventure, mystery, and immense power. It connects continents, carries vital goods, and holds secrets yet to be discovered. Now, imagine super-smart tools, like magic glasses and digital worlds, helping us build the amazing ships that sail these seas, train the brave sailors who guide them, and keep these incredible vessels running smoothly. This isn’t science fiction; it’s the exciting reality of AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance. These technologies are like a new tide, washing over the old ways and bringing waves of innovation to the entire Maritime industry.

Charting New Waters: An Introduction to AR/VR in Marine Engineering

Before we dive into the digital deep, let’s understand what Marine Engineering is all about. Think of it as the super-cool job of dreaming up, building, and taking care of almost anything that floats or works in the ocean – from gigantic cargo ships that carry goods across the globe, speedy ferries zipping passengers between islands, silent submarines exploring the depths, to massive offshore platforms like oil rigs or wind turbines standing tall in the waves. Marine engineers are like the master builders and caretakers of the sea.

Their work involves several key areas:

- Designing Ships: This is where the dream begins. Like architects drawing blueprints for a skyscraper, marine engineers and naval architects design the vessels. They figure out how big, heavy, and fast a ship should be, what shape its hull (the main body) should have, and ensure it’s strong, safe, and efficient, able to withstand the mighty forces of the ocean. They use complex calculations and drawings to plan every detail. The goal of AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance starts here, helping to visualize these complex plans.

- Building Ships (Shipbuilding): Once the design is perfect, it’s time to build! This happens in enormous workshops called shipyards, where skilled workers assemble the massive pieces of the vessel, install engines, and connect miles of pipes and wires. It’s like putting together a giant, intricate puzzle that has to be perfect. The Shipbuilding industry is a complex world of its own.

- Training Sailors (Maritime training): Ships don’t sail themselves! Marine engineers are also involved in making sure sailors know how to operate these complex machines safely and effectively. Maritime training covers everything from steering the ship and navigating by the stars (or GPS!) to running the powerful engines, handling cargo, and knowing exactly what to do in an emergency, like a fire or needing to abandon ship. This is a critical part of the Maritime industry.

- Maintaining Ships: Just like cars, ships need regular check-ups and repairs to stay in top condition. Marine engineers oversee the maintenance, fixing broken parts, cleaning systems to prevent issues like corrosion from salty seawater, and ensuring everything runs smoothly and safely, often while the ship is far out at sea. This ensures the vessel has a long and productive life.

Now, let’s look at the “magic tools” that are changing this field: AR and VR.

- Virtual Reality (VR): Imagine putting on special goggles – a VR headset – and suddenly, you’re not in your room anymore! You’re standing on the bridge of a virtual ship, exploring a digital engine room, or even swimming in a computer-generated ocean. That’s VR. It creates a completely make-believe, 3D world you can step inside and interact with. It’s like being teleported into a video game or a digital blueprint.

- Augmented Reality (AR): Think of AR as adding a layer of digital magic onto the real world around you. You might look through your phone’s camera or wear special glasses, and suddenly see helpful information pop up. Maybe it’s digital arrows showing you how to fix a real engine part, instructions floating in the air, or even a 3D model of a ship system appearing right there on the workshop floor. AR enhances your reality; it doesn’t replace it.

These two amazing technologies, VR and Augmented reality, are making huge waves in marine engineering. They are not just cool gadgets; they are powerful tools that are fundamentally changing how we approach the challenges of the sea. This article will explore the incredible journey of AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance, showing how these digital wonders are making ship design smarter, Maritime training safer and more effective, and ship maintenance faster and more efficient than ever before.

The way these technologies are used often depends on their core difference. Because VR creates a whole separate world, it’s perfect for situations where you need a fully controlled simulation, like practicing dangerous emergency drills without any real risk, or walking through a ship design that doesn’t physically exist yet. AR, on the other hand, shines when you need digital help while working in the real world – like a mechanic getting repair instructions overlaid on the actual engine, or seeing how a digital design fits into a physical shipyard space. This distinction is key to understanding the power of AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance.

👉Related Post: The Internet of Underwater Things (IoUT): Connecting the Deep with Smart Marine Tech

Dreaming Up Ships: How AR/VR Revolutionizes Design and Ship Building

Designing and building ships is an incredibly complex task. Imagine trying to draw plans for a floating city, making sure every pipe, wire, room, and piece of machinery fits perfectly and works together, all while ensuring the vessel is strong enough to handle giant waves and safe for everyone onboard. Traditionally, engineers relied on thousands of complicated 2D drawings and sometimes built expensive physical scale models to try and visualize these massive, intricate structures. This process could be slow, and it was easy for mistakes to slip through, like planning for a pipe and an electrical cable to occupy the same tiny space! Finding these “clashes” only after construction started could lead to costly delays and rework.

But now, AR and VR are acting like digital magic wands for ship designers and builders, transforming this complex process. This transformation is a central part of AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance.

Virtual Prototyping: Building Ships Before Building Ships. One of the most exciting uses of VR technology is virtual prototyping. Imagine putting on a Vr headset and walking through a full-size, completely detailed digital version of a ship before a single piece of steel is cut. Engineers can explore every nook and cranny, from the bridge down to the engine room, checking if equipment fits, if walkways are clear, and if maintenance access is easy. This “digital twin” allows teams to catch design flaws, like those pesky pipe clashes, incredibly early in the process. Finding a problem in the virtual world costs almost nothing to fix compared to fixing it during the actual shipbuilding phase, saving enormous amounts of time and money. This ability to perfect the design virtually is a huge benefit of AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance.

Immersive Design Reviews: Meeting Inside the Model VR also changes how teams collaborate on designs. Instead of huddling around drawings or computer screens, designers, engineers, shipyard managers, and even the ship’s future owners can put on VR headsets and meet inside the virtual ship model together. They can walk around, point out features, discuss changes, and make decisions in a shared, immersive space, regardless of their physical location. This leads to much clearer communication, better understanding of the design by everyone involved, and faster agreement on changes. This collaborative power makes the design process more accessible and efficient, moving beyond just the specialists and allowing broader input much earlier. This shift democratizes the design review, a key evolution driven by AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance.

Clash Detection: No More Bumping Pipes! A major headache in traditional shipbuilding is discovering late in the process that different systems, like plumbing, electrical wiring, and ventilation ducts, are designed to occupy the same space. VR makes spotting these “clashes” much easier. By exploring the detailed 3D model immersively, engineers can visually identify potential conflicts long before construction begins. Specialized software, often integrated with VR tools, can also automatically detect these clashes. Finding and fixing these issues digitally saves significant rework, material waste, and delays during the physical build. This error reduction is a core value proposition of AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance.

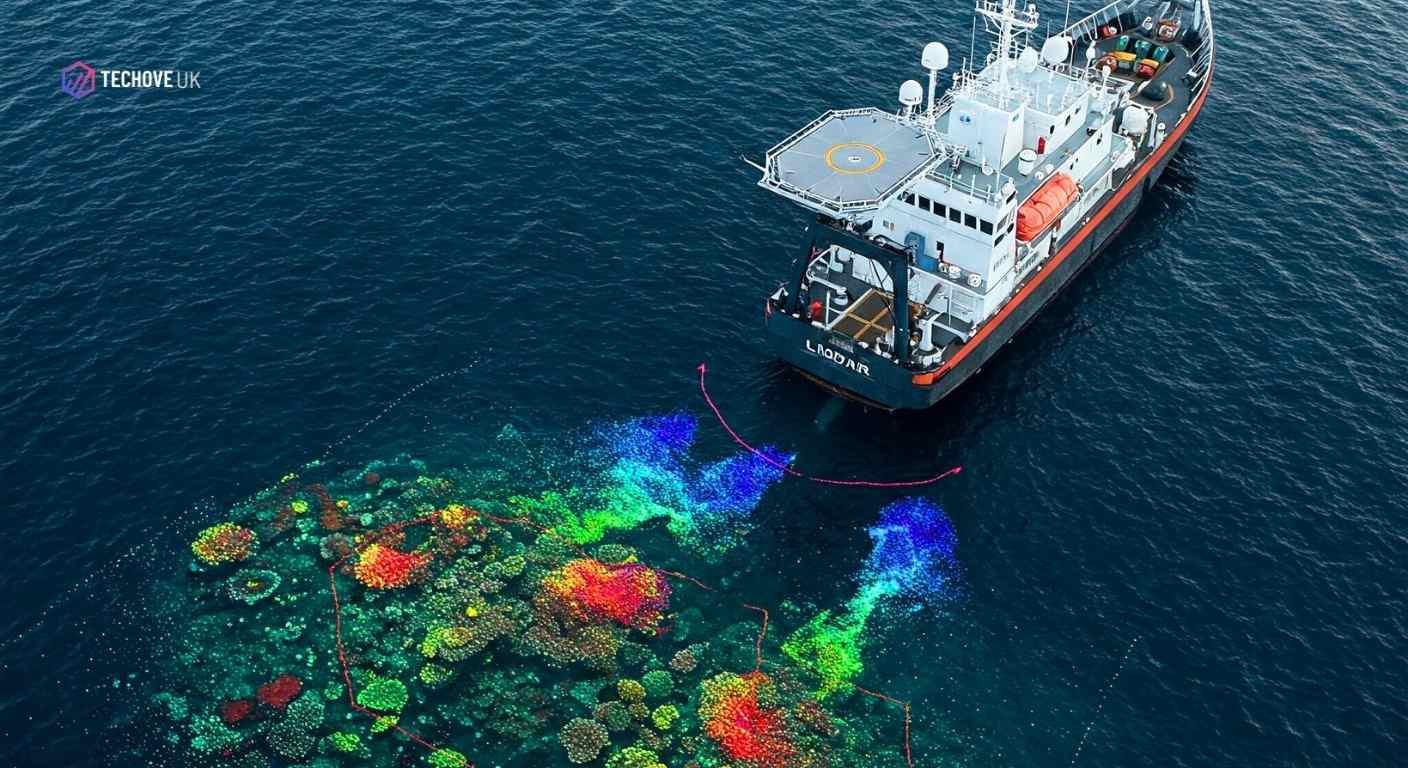

AR for Real-World Visualization Augmented Reality brings the digital design into the physical world. Shipbuilders on the yard floor can use tablets or AR glasses (like Microsoft HoloLens) to see a 3D overlay of the design projected onto the actual ship section they are working on. This helps them visualize exactly where components need to be installed and how pipes should be routed, or check if a built section matches the digital plan precisely. It bridges the gap between the digital blueprint and the physical reality of shipbuilding.

The Software Behind the Magic: Cadmatic. Creating and managing these complex digital ship models requires powerful software. Companies like Cadmatic are leaders in providing these tools for the Maritime industry. Cadmatic offers specialized Computer-Aided Design (CAD) and Product Lifecycle Management (PLM) software tailored to the challenges of the shipbuilding industry. Their software helps create detailed 3D models (often called digital twins) that contain vast amounts of information about the ship.

Crucially, Cadmatic integrates AR, VR, and Mixed Reality (MR) capabilities into its platform. Tools like Cadmatic eShare allow multiple users to access and visualize this complex ship data through VR headsets or AR devices like the HoloLens. This enables immersive design reviews and real-world visualizations, which were mentioned earlier. Cadmatic is also involved in forward-looking projects like the “Virtual Sea Trial,” which aims to use digital environments and tools like eShare, enhanced with AR/VR and AI, to test ship systems virtually before actual sea trials, further reducing costs and risks, especially for green technologies.

Boosting Mechanical Engineering Precision. For the Mechanical engineering aspects of ship design, AR/VR tools are invaluable. Engineers can virtually place and examine complex machinery, engines, and propulsion systems within the tight confines of a ship’s hull. They can visualize intricate pipe routes and ensure that there is enough space for installation and, importantly, for future maintenance access. This leads to more efficient, reliable, and easier-to-maintain Mechanical engineering systems onboard. The precision and foresight offered by AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance are transforming this discipline.

Design Benefits: A Sea Change. The impact of AR/VR on ship design and shipbuilding is profound. Key benefits include:

- Massive Error Reduction: Catching clashes and design flaws early prevents costly rework. Studies in related fields and shipbuilding report dramatic reductions in errors, sometimes over 90%.

- Faster Design Cycles: Virtual prototyping and collaborative reviews speed up decision-making and reduce the need for physical models.

- Better Collaboration: Teams can work together more effectively, regardless of location.

- Significant Cost Savings: Avoiding rework, reducing material waste, and shortening timelines translate to major financial benefits. Some estimates suggest potential savings of 10-50% in shipyard costs.

The powerful return on investment (ROI) demonstrated in various case studies provides a strong argument for adopting these technologies, helping to overcome the initial investment concerns. Transforming the design phase is truly a cornerstone of AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance.

Learning the Ropes in a Virtual Ocean: The Power of VR Training in the Maritime Industry

Sailing the vast oceans requires incredible skill and knowledge. Seafarers, the brave men and women who operate our ships, need rigorous Maritime training to ensure the safety of their vessel, their crew, the cargo, and the environment. They must master complex navigation techniques, understand intricate engine systems (Mechanical engineering), and be prepared to handle high-stress emergencies like fires or storms, often adhering to strict international standards like STCW (Standards of Training, Certification and Watchkeeping).

However, traditional Maritime training methods face significant challenges. Building and maintaining large physical simulators (like full-scale ship bridges or engine rooms) is extremely expensive. Using real ships for training is often impractical due to cost and operational schedules. Most importantly, practicing dangerous emergency procedures like firefighting or abandon ship drills in real life carries inherent risks. Furthermore, access to high-quality training facilities can be limited for cadets and seafarers in certain locations. Insufficient training can, unfortunately, contribute to human error at sea.

This is where VR technology enters the scene, offering a revolutionary approach to Maritime education and Maritime training. By putting on a Vr headset, trainees are instantly transported into incredibly realistic, interactive 3D simulations of ship environments. They aren’t just watching a screen; they are in the virtual world, able to look around, walk, interact with equipment, and experience scenarios firsthand. This immersive quality makes AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance a powerful tool for learning.

Step Aboard These VR Training Simulations:

VR technology allows for a wide range of training scenarios critical for seafarers:

- Ship Navigation and Handling: Trainees can practice steering massive vessels through virtual storms, navigating congested harbors, docking safely, and using essential bridge equipment like radar and ECDIS (Electronic Chart Display and Information System) – all without leaving the classroom. They can experience different weather conditions and practice collision avoidance rules (COLREGs) repeatedly.

- Engine Room Operations: Future marine engineers can explore a virtual engine room, learn to operate complex machinery like pumps, generators, and boilers, practice routine maintenance tasks, and crucially, learn to diagnose and respond to simulated equipment failures and alarms. This hands-on practice in a virtual setting builds vital Mechanical engineering skills safely.

- Emergency Procedures: This is where VR training truly shines. Trainees can face virtual fires (learning to handle different types like Class A, B, or electrical fires ), practice abandon ship procedures using virtual life rafts, respond to simulated man-overboard situations, and learn how to manage hazardous material incidents – all with zero physical risk. This safe repetition builds confidence and life-saving muscle memory. This safety enhancement is a major achievement of AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance.

- Cargo Handling: Different ships carry different cargo, each with specific handling procedures. VR can simulate loading and unloading operations for various cargo types, ensuring trainees learn the correct and safe methods.

- Safety Protocols: Basic but vital skills like using Personal Protective Equipment (PPE) correctly, performing damage control assessments, or executing mooring operations can be practiced and reinforced in VR.

The Wave of Benefits from VR Training:

The advantages of using VR technology with a VR headset for Maritime training are numerous and compelling:

- Unmatched Safety: The ability to practice high-risk, dangerous scenarios (like firefighting or navigating in severe weather) in a completely safe virtual space is perhaps the biggest benefit.

- Boosted Skills and Memory: Learning by doing, even virtually, is incredibly effective. The immersive nature of VR leads to better understanding, faster skill acquisition, and significantly higher knowledge retention compared to traditional methods like lectures or reading. Some studies suggest retention rates can jump to 75% with VR, compared to just 10% for lectures. Trainees learn faster too, sometimes up to four times quicker.

- Cost Savings Ahoy!While there’s an initial investment in VR gear (VR headsets, computers) and software, the long-term savings can be huge. VR drastically reduces the need for expensive physical simulators, fuel for training vessels, travel costs for trainees and instructors, and physical materials. VR training scales easily – adding more trainees often just means adding more headsets, not building another simulator room. The return on investment (ROI) can be very attractive.

- Train Anywhere, Anytime: VR training systems are portable and can be set up almost anywhere, from classrooms to potentially even onboard ships. This makes high-quality training accessible to more people, regardless of location, and offers flexibility in scheduling.

- Consistent Quality: VR ensures every trainee receives the same high-quality, standardized training experience, which is crucial for meeting global standards like STCW.

- Smart Assessment: Modern VR training systems can track a trainee’s actions, monitor performance, identify mistakes, and provide immediate, objective feedback, helping learners improve faster. AI can even be integrated for automated assessment.

This ability to provide realistic, hands-on practice for critical skills, which was previously constrained by cost and safety, is perhaps the most significant impact of VR. It opens the door for more seafarers worldwide to access high-fidelity training, potentially leading to a safer and more competent global workforce. The dramatic improvements in learning speed and retention also make a strong case for efficiency, addressing the industry’s need for effective upskilling. This makes AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance not just innovative, but potentially transformative for workforce development.

The Future Horizon of Maritime Education: VR technology is rapidly moving from a novelty to a standard tool in Maritime education. The future looks even more exciting, with trends like:

- Haptic Feedback: Gloves or controllers that let trainees “feel” virtual objects, like the vibration of an engine or the resistance of turning a valve.

- Multiplayer Drills: Allowing entire crews to train together in the same virtual simulation, practicing teamwork and communication during emergencies.

- AI-Powered Assessment: Smarter systems that analyze performance in detail and provide personalized feedback.

- Cloud-Based Training: Making sophisticated VR simulations accessible globally via the internet.

This constant evolution underscores the deep and ongoing transformation that AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance is bringing to how we prepare seafarers for the challenges of the sea.

Table: Benefits of VR Maritime Training vs. Traditional Methods

| Feature | Traditional Training | VR Training |

| Safety | High risk for dangerous scenario practice | Risk-free virtual environment for all scenarios |

| Cost | High initial & ongoing (simulators, travel, fuel) | Higher initial hardware/software cost, but lower ongoing costs (less travel, no fuel, reusable) |

| Knowledge Retention | Lower (e.g., 10% from lectures) | Significantly Higher (e.g., up to 75%) due to immersive experience |

| Learning Speed | Standard pace | Faster (up to 4x) |

| Accessibility | Limited by the physical location of simulators/ships | Highly portable systems allow training anywhere, anytime |

| Realism | Varies; physical simulators can be high, but limited | The high degree of immersion and realism is possible in virtual environments |

| Practice Repetition | Limited by cost, time, and risk | Unlimited repetition is possible for skill mastery |

| Assessment | Often subjective, requires instructor observation | Objective, data-driven performance tracking and feedback are possible |

Keeping Ships Shipshape with Digital Eyes: Augmented Reality in Maintenance

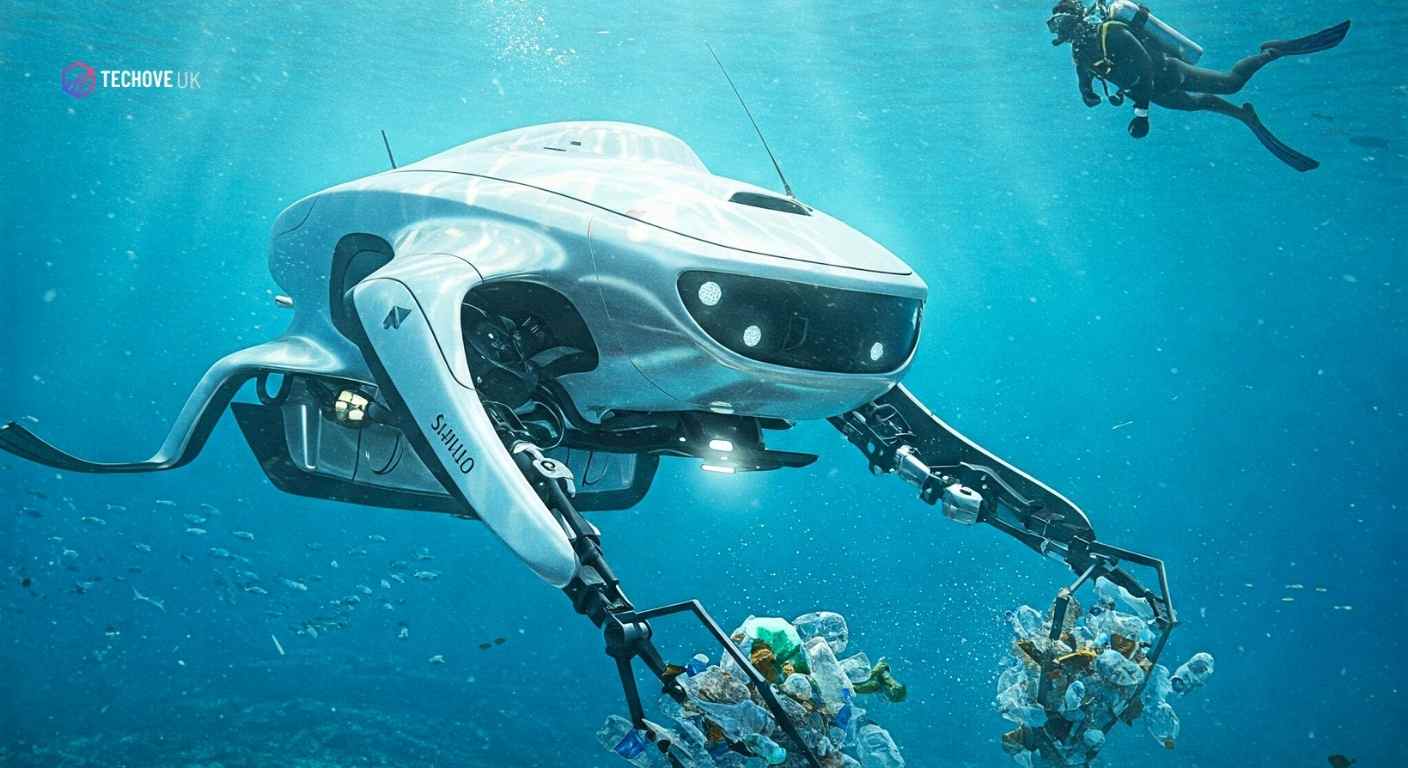

Ships are like floating factories – incredibly complex machines filled with engines, generators, pumps, navigation systems, and miles of pipes and wires. Keeping all this equipment running perfectly is a huge challenge, especially since ships operate in harsh saltwater environments and are often far from land-based workshops or expert help. When something breaks down at sea, getting the right parts or the right expertise quickly can be difficult and expensive. Downtime, when a ship can’t operate, costs the Maritime industry a lot of money.

This is where Augmented Reality (AR) comes to the rescue, acting like a pair of digital super-eyes or a remote expert whispering in the technician’s ear. AR technology, often delivered through smart glasses or tablets, overlays digital information onto the technician’s view of the real world, making maintenance tasks smarter, faster, and safer. This maintenance revolution is a vital part of AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance.

How AR Helps Onboard:

- Real-time Information Overlays: Imagine a technician looking at a complex engine part. With AR glasses, they could instantly see digital labels identifying components, real-time sensor data (like temperature or pressure), or step-by-step repair instructions floating right next to the physical object. No more flipping through bulky paper manuals or trying to match diagrams to reality! AR provides the needed information exactly when and where it’s needed.

- Remote Expert Assistance (“Tele-Maintenance” ): This is one of AR’s superpowers in the maritime industry. A crew member or field engineer on a ship facing a tricky problem can put on AR glasses equipped with a camera and microphone. Back on shore, an expert specialist can see exactly what the person on the ship sees, in real-time. The expert can then talk the technician through the repair, drawing arrows or highlighting parts directly in their field of view using the AR display. It’s like having the world’s best mechanic virtually teleported onto the vessel, 24/7. This capability drastically reduces the need for experts to travel, saving time and money. Even if there’s no live connection (like a poor satellite signal), the technician can record video and photos with the glasses to send later.

- Visualizing Hidden Parts: Ships have complex systems hidden behind panels or inside machinery. AR can act like X-ray vision, showing technicians the location of pipes, wires, or components that are normally out of sight. This helps them plan repairs more effectively and avoid accidentally damaging hidden systems.

- Streamlining Inspections: AR can guide inspectors through complex checklists, overlaying required checks onto the equipment. It can automatically record findings, take photos, and generate reports, making the inspection process faster and more consistent.

Industry Leaders Like Wartsila Embrace AR: Major marine technology companies are already putting AR into practice. Wartsila, a well-known name in marine engines and systems, uses augmented reality, specifically smart glasses and remote guidance software, for its Seals & Bearings services. They have successfully tested and piloted this technology, allowing their shore-based experts to remotely assist engineers onboard ships or in shipyards with tasks like troubleshooting, inspections, repairs, and even new equipment commissioning. This provides immediate access to Wartsila’s global expertise, saving customers time and money. Other companies like ABB also offer similar AR remote support solutions. The U.S. Marine Corps is also experimenting with AR for tele-maintenance to modernize its capabilities.

Reaping the Benefits of AR Maintenance: The advantages of using Augmented reality for ship maintenance are clear and significant:

- Faster Fixes: AR dramatically speeds up troubleshooting and repair times by providing instant information and expert guidance. Case studies from related industries show impressive time reductions, sometimes cutting repair times by nearly half.

- Fewer Mistakes: Clear, visual, step-by-step instructions overlaid on the task reduce the chance of errors.

- Lower Costs: Saving expert travel time, reducing ship downtime, preventing errors, and optimizing repairs all lead to significant cost savings.

- More Uptime: Faster and more effective maintenance means ships spend less time being repaired and more time doing their job.

- Better Safety: Having clear guidance, visualizing hidden components, and getting expert help can make potentially hazardous maintenance tasks safer for the crew.

AR effectively bridges the knowledge gap that often exists on vessels far from shore. By connecting on-site crew, who may have less specialized experience, with central experts, AR acts as a powerful force multiplier. It democratizes expertise, making high-level support instantly available where it’s needed most, leading to quicker, more reliable repairs.

Looking ahead, the power of AR in maintenance is set to grow even further. Imagine combining AR overlays with real-time data streaming from sensors on the equipment (the Industrial Internet of Things, or IIoT) and using Artificial Intelligence (AI) to predict potential failures before they happen. AR could then guide technicians through preventative maintenance tasks based on these predictions. This shifts maintenance from being reactive (fixing things after they break) to proactive and data-driven, further boosting efficiency and reliability. This evolution represents the next wave in the maintenance transformation driven by AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance.

Riding the Digital Wave: AR/VR Growth and Impact (2020-2024 Statistics)

The potential of Augmented Reality (AR) and Virtual Reality (VR) to revolutionize marine engineering isn’t just a futuristic dream; it’s a trend backed by significant growth and measurable results, especially in the period from 2020 to 2024. While we’ve explored how these technologies are changing design, training, and maintenance, let’s now look at the numbers that show the rising tide of adoption and the real-world impact of AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance.

Market Growth: A Swelling Tide

The global market for AR and VR technologies has exploded in recent years. Reports show staggering growth:

- One estimate valued the combined AR/VR market at USD 22.12 billion in 2024, projecting it to soar to USD 96.32 billion by 2029, representing a compound annual growth rate (CAGR) of 34.2%.

- Another forecast suggests the market could grow by a massive USD 442.9 billion between 2024 and 2028, accelerating at an even higher CAGR of 50.22%.

- Focusing on VR, one report estimated the market at USD 15.9 billion in 2024, expected to reach USD 38.0 billion by 2029 (CAGR 19.1%).

- Looking back, the broader neurotechnology market (which includes AR/VR interfaces) was valued at around USD 12.82 billion in 2022 and projected to grow significantly, with other reports showing similar strong growth trajectories from 2020 onwards. For instance, one report tracked growth from $9.3 billion in 2020 towards $21.9 billion by 2026 (CAGR 15.3%).

While specific figures for AR/VR adoption solely within the Maritime industry might be harder to isolate in broad market reports, the overall trend is undeniable. Industries with similar complexities, such as manufacturing, aerospace, defense, construction, and healthcare, are rapidly adopting these technologies. Furthermore, the maritime digitization market itself is booming, expected to grow from $220.27 billion in 2024 to $333.45 billion by 2029 (CAGR 10.9%), driven by trends like autonomous vessels and smart ports. Given that key maritime players like Wartsila and Cadmatic are actively implementing AR/VR solutions , and the industry faces pressures to improve efficiency, safety, and sustainability, it’s clear that the massive growth in the general AR/VR market is significantly influencing and enabling adoption within marine engineering. This widespread technological advancement fuels the progress of AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance.

Quantifiable Benefits: Measuring the ROI

The investment in AR/VR is paying off with tangible benefits, providing a strong Return on Investment (ROI) across various applications relevant to marine engineering:

- Vr Training Efficiency & Cost Savings:

- Faster Learning: Studies consistently show VR training significantly reduces the time needed to reach competency, often by 40% or more, and sometimes up to four times faster than traditional methods.

- Better Retention: Learners remember more of what they learn in immersive VR environments – retention rates can be as high as 75% compared to much lower rates for lectures or reading. A University of Maryland study showed an 8.8% improvement in recall accuracy.

- Cost Reduction: VR cuts costs associated with travel, physical simulators, equipment usage, and materials. The US Navy, for example, realized $4.24 million in avoided costs from just one VR training program, yielding an ROI of $2.96 million on a $1.28 million investment. UPS saw a 75% reduction in driver training time using VR. These savings make AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance financially viable.

- Design & Production Error Reduction:

- Fewer Mistakes: Using VR for design reviews and virtual prototyping catches errors early, drastically reducing costly rework during Ship building. Some projects report error reductions of up to 92%.

- Cost Avoidance: Identifying clashes or ergonomic issues virtually avoids significant construction costs. One construction project averted over $475,500 in costs using VR. Shipyards estimate savings of 10-50% are possible through such digital methods. Mazagon Dock Shipbuilders significantly reduced inspection times using VR. This impact on the Shipbuilding industry underscores the value of AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance.

- Maintenance Time & Cost Reduction:

- Faster Repairs: AR guidance helps technicians diagnose and fix problems much faster. Studies show repair times reduced by 45-47%.

- Reduced Costs: Eliminating expert travel, minimizing downtime, and preventing errors through AR support leads to substantial cost savings. One analysis calculated an ROI of over 42% for an industrial AR maintenance project, with payback in about three years. This efficiency gain is central to AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance.

Investment Trends: Fueling Maritime Education with Vr Technology

The rapid growth is fueled by significant investment. Venture capital firms are pouring money into AR and VR startups globally. While not all are maritime-specific, this overall investment drives down hardware costs (Vr headsets becoming more affordable ) and spurs software innovation applicable across industries.

Specifically for education and training, the VR market is seeing dedicated growth. Forecasts predicted the education VR market could reach $12.6 billion by 2025. Maritime education institutions are part of this trend, increasingly exploring and adopting Vr technology for training. Studies like the one at National University Odessa Maritime Academy, which found VR improved navigator cadet learning quality by nearly 26%, demonstrate its effectiveness in this specific field. This investment and adoption in Maritime training are crucial for realizing the full potential of AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance.

Table: Reported ROI & Benefits of AR/VR in Industrial Applications (Relevant to Marine Engineering, 2020-2024 Focus)

| Application Area | Technology | Reported Benefit | Example/Source |

| Training | VR | 40-75% Reduction in Training Time | General studies , 4x Faster Learning |

| Training | VR | Up to 75% Knowledge Retention | Compared to 10% lecture , 8.8% recall accuracy improvement |

| Training | VR | Significant Cost Savings (Travel, Facilities, Equipment) | General benefit , Navy ROI example , UPS example |

| Training | VR | 70% Improvement in Employee Performance | General study |

| Training | VR | 70% Reduction in Workplace Injuries (Ford example) | Safety training benefit |

| Training | VR | ~26% Improvement in Learning Quality (Maritime Cadets) | NU OMA Study |

| Design/Production | VR | 92% Reduction in Production Errors | Shipbuilding case study |

| Design/Production | VR | 10-50% Overall Cost Savings | Shipyard estimates |

| Design/Production | VR | 60-65% Reduction in Design Issues | Nvidia report |

| Design/Production | VR | Avoided $475,500+ in Construction Costs | Penn State Ice Rink case study |

| Design/Production | VR | 50% Reduction in Physical Prototypes (SEAT example) | Automotive case study |

| Design/Production | VR | 30% Reduction in Production Time (SEAT example) | Automotive case study |

| Design/Production | VR | Significant Reduction in LOI Time (Mazagon Dock example) | Shipbuilding case study |

| Maintenance | AR | 45-47% Faster Repair Times | Industrial / USMC studies |

| Maintenance | AR | Reduced Errors | General benefit , USMC AR trial |

| Maintenance | AR | Significant Cost Savings (Reduced Travel, Downtime) | General benefit |

| Maintenance | AR | 42.3% ROI, ~3 Year Payback | Industrial AR maintenance case study |

The confluence of maturing technology (better, cheaper headsets, sophisticated software like Cadmatic’s ), clear evidence of substantial ROI across relevant applications, and strong industry drivers (need for efficiency, safety, sustainability, skilled workers ) created a powerful momentum for AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance adoption between 2020 and 2024, setting the stage for even wider implementation in the years ahead. Navigating Your Curiosities: Frequently Asked Questions (FAQs)

As these exciting AR and VR technologies make bigger waves in the world of ships and oceans, it’s natural to have questions! Let’s answer some common queries about AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance!

- What is VR used for in maritime training?

Think of Virtual Reality (VR) as a super-advanced simulator for sailors and marine engineers. Using a Vr headset, trainees step into realistic, computer-generated ships and scenarios to practice skills safely. Key uses include:

- Emergency Drills: Practicing firefighting techniques, learning how to abandon ship using virtual lifeboats, or responding to a man-overboard situation without any real danger. This makes Vr training incredibly valuable for safety.

- Ship Handling & Navigation: Learning to steer different types of ships, navigate through storms or busy ports, use radar and electronic charts (ECDIS), and practice docking maneuvers.

- Engine Room Operations: Exploring complex engine rooms virtually, learning how to operate machinery, troubleshoot problems, and practice emergency shutdown procedures. This is great for Mechanical engineering training.

- Cargo & Safety Procedures: Practicing the correct ways to handle different types of cargo or use safety equipment like personal protective gear (PPE).

Overall, Vr training makes learning more engaging and memorable, helps sailors build critical skills and muscle memory through safe repetition, and is often more cost-effective than traditional methods. Improving skills safely and effectively is a vital part of AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance.

- How does Augmented Reality help in ship maintenance?

Augmented Reality (AR) acts like a high-tech helper for technicians working on ships. Using AR glasses or a tablet, they can see digital information overlaid onto the real equipment they are looking at. This helps in several ways:

- Digital Instructions: Technicians can see step-by-step guides, diagrams, or checklists projected directly onto the machine they are fixing.

- Remote Expert Help: If a technician gets stuck, they can use AR glasses to share their view with an expert back on shore. The expert sees exactly what the technician sees and can provide live guidance, drawing arrows or instructions into the technician’s view. Companies like Wartsila use this technology effectively.

- Seeing the Unseen: AR can help visualize parts like pipes or wires that are hidden behind panels or inside complex machinery.

- Instant Data Access: Technicians can instantly pull up maintenance history or real-time sensor data for the equipment they are working on.

This makes repairs much faster, reduces errors, saves money on travel and downtime, and can even improve safety. This transformation in maintenance is a key benefit of AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance.

- Is AR/VR technology expensive for the maritime industry?

There is an upfront cost to get started with AR/VR, including buying Vr headsets or AR glasses, powerful computers, and developing or purchasing the specialized software. However, the story doesn’t end there! Many companies find that AR/VR actually saves them a lot of money over time.

Here’s how:

- Vr training cuts down on expensive travel, the need for multi-million dollar physical simulators, and using real ships for practice.

- Using AR/VR during the design phase helps catch mistakes early, preventing very expensive rework during the actual Ship building process.

- AR for maintenance means experts don’t always need to travel to the ship, and repairs get done faster, reducing costly downtime when the ship isn’t operating.

So, while it costs money to start, the return on investment (ROI) – the amount saved or gained compared to the cost – is often very positive, making it a worthwhile investment for many in the Maritime industry.

- What are the main benefits of using AR/VR in shipbuilding design?

Using AR and VR in the design stage of Ship building brings some fantastic advantages:

- See It Before You Build It: Engineers and designers can virtually walk through a full-size digital model of the ship. This gives a much better sense of the space, layout, and how everything fits together compared to just looking at drawings.

- Catch Mistakes Early: It’s much easier to spot potential problems in the 3D virtual model, like pipes trying to run through the same spot (clash detection) or equipment being hard to reach for maintenance. Finding these issues early saves a lot of money and time compared to fixing them during construction.

- Work Together Better: Design teams, shipyard workers, and even the ship owners can meet inside the virtual ship to review the design, discuss changes, and make decisions together, even if they are in different parts of the world.

- Less Need for Physical Models: Building large physical mock-ups can be expensive and time-consuming. Virtual prototypes allow for testing and refinement digitally.

- Happy Clients: Ship owners get a much clearer understanding of the design early on, which helps speed up approvals and ensures the final ship meets their expectations. Powerful software from companies like Cadmatic helps make all this possible.

- Which companies are leading in AR/VR solutions for marine engineering?

The field of AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance is dynamic, with several key companies driving innovation:

- Wartsila: A major player known for using Augmented reality (AR) and smart glasses to provide remote maintenance support and expertise for marine equipment like seals, bearings, and navigation systems.

- Cadmatic: A leading provider of ship design software (CAD/CAM) that heavily integrates AR, VR, and MR technologies for immersive design reviews, visualization, and data management through platforms like eShare. They are actively involved in collaborative projects like the Virtual Sea Trial to push the boundaries of digital shipbuilding.

- FORCE Technology: This company collaborates with VR hardware providers like Varjo to create high-fidelity VR/XR simulators specifically for Maritime training, offering cost-effective and immersive learning experiences.

- ABB: Another major industrial technology company offering AR-based remote assistance solutions that are applicable to the Maritime industry.

- Specialized Training Providers: Many other companies and maritime academies are developing and utilizing VR simulations for various aspects of Maritime training and Maritime education.

The practical questions people ask highlight a focus on real-world value. Users want to know how AR/VR helps with specific tasks like training and maintenance, if the benefits justify the cost, what specific problems it solves in design, and who provides these solutions. This shows that the interest in AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance is moving beyond novelty towards practical implementation and tangible results within the Maritime industry.

Setting Sail for the Future: Conclusion

The voyage into the world of AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance reveals a technology that is far more than just a futuristic novelty. It’s a powerful tide reshaping the shores of the Maritime industry. We’ve seen how Virtual Reality allows engineers to walk through ships before they’re built, catching errors and fostering collaboration in ways previously impossible. We’ve explored how Vr training immerses sailors in realistic, yet perfectly safe, environments, honing critical skills for navigation, engine room operations (Mechanical engineering), and emergency response with unprecedented effectiveness and accessibility. And we’ve witnessed how Augmented reality equips maintenance crews with digital superpowers, providing instant information and expert guidance right at the point of need, keeping complex vessels shipshape and reducing costly downtime.

This technological shift isn’t just about doing the same things faster or cheaper, although the efficiency gains and cost savings are substantial. It’s about fundamentally improving the way the Maritime industry operates. By reducing design errors and enabling virtual testing, AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance contributes to building better, potentially more sustainable ships. By making high-quality Maritime training safer and more accessible, it enhances the skills and safety of seafarers worldwide. By streamlining maintenance, it increases the reliability and operational life of vessels. These technologies are also helping to attract a new generation of talent to the vital Shipbuilding industry and the broader maritime sector by making complex tasks more intuitive and engaging.

The journey is far from over. The future promises even more integration, with AR and VR merging seamlessly with Artificial Intelligence (AI) and the Internet of Things (IoT). Imagine AI analyzing sensor data to predict a fault, and AR guiding a technician through the preventative repair, or VR simulations that adapt in real-time based on a trainee’s performance. Hardware like Vr headsets and AR glasses will continue to become more powerful, comfortable, and affordable.

However, the success of this digital transformation relies on more than just the technology. It requires thoughtful integration into existing workflows, addressing challenges like connectivity at sea and the need for standardization. Most importantly, it requires a human-centric approach. AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance is most powerful when it augments the skills, knowledge, and judgment of the talented people working in the Maritime industry, empowering them rather than replacing them.

Like a skilled navigator using a revolutionary new compass, the Maritime industry is using AR and VR to chart a course towards a future that is more innovative, efficient, safer, and sustainable. The digital tide is rising, and AR/VR in Marine Engineering: Transforming Design, Training, and Maintenance is steering the ship towards exciting new horizons.